Browse Our Catalog of Industrial Knives

-

Crown Cutter Raised Center 40x40x20mm Compatible with Vecoplan® Equipment

LEARN MORE →$299

-

Wiper Insert 40x40x25mm Compatible with Vecoplan® Equipment

LEARN MORE →$299

-

Nelmor Model AN1010M-1, G810M-1 Bed Knife

LEARN MORE →$299

-

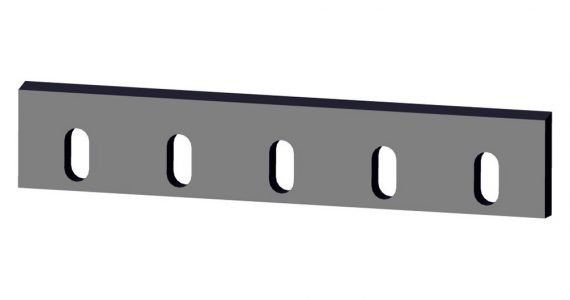

1620 Twin Shear Bed Knife Compatible with Cumberland Model Equipment

LEARN MORE →$299

Welcome to Cutting Edge Knives!

Pelletizing Knives

Granulator Knives

Browse Our Catalog of Pelletizing Knives

-

Beringer Compatible 3.281 Inch Pelletizing Knife – M2

LEARN MORE →$299

-

NGR Compatible 1.732 Inch Pelletizing Knife – M2

LEARN MORE →$299

-

Gala Compatible 1.275 Inch Stepped Pelletizing Knife – M2

LEARN MORE →$299

-

Erema Compatible 2.283 Inch Pelletizing Knife

LEARN MORE →$299

Regrinding Services

Contact Us

Contact Us

We will get back to you as soon as possible

Please try again later

FAQs

-

Can you tell me more about your company?

At Cutting Edge Knives, Inc., we specialize in manufacturing and distributing industrial knives and blades for all of your industrial applications and needs. We produce premium machine knives at prices that you simply won’t find anywhere else! Here at Cutting Edge Knives, we pride ourselves on producing truly exceptional products. Our machining capabilities allow us to produce exactly what our clients are looking for. Whether you’re in the market for something off the shelf or custom made, we will work with you to identify the right blade for your specific needs, reducing downtime, extending blade life, and improving throughput. We understand how important it is that you are able to work with knives of impeccable quality, both for performance and safety reasons. Our goal is to make sure you’re always working with the most exceptional knives available. In addition to the manufacturing and distributing of industrial knives, we also offer regrind services. We’ll regrind your knives so that they’re as sharp and precise as new, saving you both time and money. At Cutting Edge Knives, we provide the best industrial knives on the market at unbeatable prices. Feel free to browse through our extensive catalog of industrial knives, granulator knives, plastic recycling knives, shredder knives, granulator blades, pelletizing knives, shredder screens, granulator screens, and more. When you are ready to place an order, want to inquire about our regrind services, or have a question about our custom industrial knives, give us a call or contact us using the contact form on our website. When you give us a call, you’ll be connected directly to our owner, ensuring that you get the best possible service available.

-

How can I place an order?

To place an order, please give us a call at (412) 279-9350, email Lorraine@cuttingedgeknife.com, or fill out our contact form with a detailed message. If you are ordering a custom machine knife, we may ask you to provide sketches and dimensions to our email address. If you are ordering a part from our catalog, please include the part number in your message. If you have any questions about custom orders or the ordering process, please don’t hesitate to contact us. We look forward to hearing from you!

Blanket Orders are encouraged for knife purchases made repetitively during the year. This will allow us to provide stable pricing and supply.

*Quotes are valid for 30 days after issue. This is due to fluctuating material pricing.*

-

Why should I sharpen my industrial knives and blades with your company?

There are many reasons to sharpen your industrial knives and blades with a professional such as Cutting Edge Knives. It’s common to drop off your knives at the local general machine store, but using a general machine store and not an expert who understands your industrial knives and blades could negatively impact your cutting operation. When you work with Cutting Edge Knives, you can rest assured knowing that your industrial knives and blades are in the hands of an expert who understands them. We have knowledge of metallurgy, abrasives, and cutting applications which allows us to choose the correct combination of wheels and segments for your material. Our skilled technicians can determine the exact combination of wheels and segments that will give you a superior cutting edge.

In addition to having the necessary knowledge, at Cutting Edge Knives, we also have the correct grinding equipment. Not all grinding equipment and operations are created equally. When you bring your industrial knives and blades to a general machine store, chances are they will be grinding on the wrong type of equipment without the right type of coolant. This can lead to micro-fractures which can lead to large cracks and then to knives blowing up. You can avoid this huge safety hazard by taking your equipment to a knowledgable professional such as Cutting Edge Knives. We have the expertise and knowledge to help identify problems based on the wear patterns, cracks, and other damage. We inspect every knife before we sharpen it and we will let you know when it’s time to replace the knife when it can no longer be returned to working condition

-

How can I increase the life of my granulator knife?

When the life of your granulating blade is optimized, your production lines experience less downtime, your work environment is safer, and your output is consistent and reliable. To increase the life of your granulator blade, utilize a precision granulator knife sharpener, establish an appropriate feed rate, and accurately set the gap between your granulator blades. All of these steps will ensure the highest possible efficiency from your operation.

-

How do I know if my granulator blade is performing as efficiently as possible?

Preventative maintenance can save your operation hours of unplanned downtime in addition to increasing the safety of the processing environment. In order to avoid unnecessary downtime, it is important to know how to recognize the early warning signs of a maintenance condition.

To know if your granulator is working too hard, check the amp readings of your granulator just after maintenance, note the values, and then use this as a baseline. This baseline will help you determine when your granulator is working harder than it should. When amp readings increase this means the granulator blade is starting to dull and it’s time to change or sharpen the blades. A dull blade will also cause your granulator to lose efficiency and run hotter. As your granulator draws in more electricity, the internal temperate of the machine increases. This can lead to dangerous fire conditions and decreases the overall life of your granulator.

To keep your granulator performing at its best make sure the gap between granulator knives is properly set and the gaps are consistent. The best gap size for your machine will be determined by the material being cut and machine specifications. If the particle sizes are uniform and you are still experiencing efficiency issues, your granulator knives may be wearing too quickly. An improper feed rate, imperfect blade material selection, and dirty and mixed material can all cause your granulator blades to wear prematurely.

We specialize in manufacturing and distributing knives and blades for all of your industrial applications.

/* Background pattern from Toptal Subtle Patterns */

Quick Links

Contact info

Industrial Knives

All Rights Reserved | Cutting Edge Knives, Inc.